The maximum machining accuracy of Qusheng Precision's products is:

Diameter tolerance of processed products: ±0.3um, roundness ±0.3um, coaxiality ±0.3um, surface roughness Ra0.015, Rz0.2. The outer diameter processing range is 0.03mm to 800mm, and the length processing range is 0.3mm~2300mm (the disassembly is not restricted)

Customized parts are communicated and processed as required.

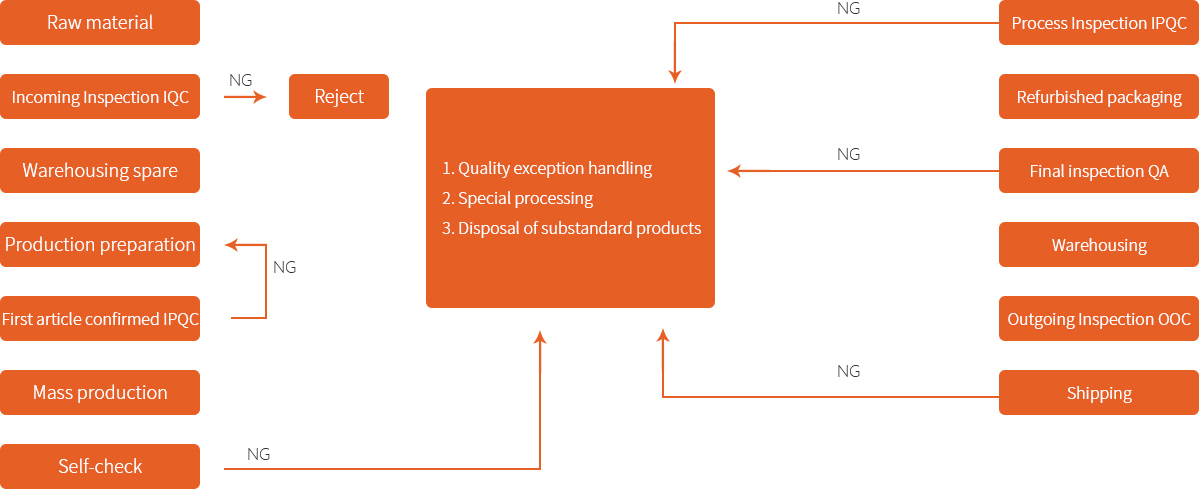

Qusheng processing steps

Qusheng Precision Co., Ltd. is divided into 7 steps in terms of product quality:

One, check the material source Various materials are available: tungsten carbide, WS (tool steel), HWS (High carbon high chrome steel), HSS (High-speed steel), Vanadis 23 (High performance powered high-speed steel), WAS (Hot working steel), CPM 10V (High performance powered high-speed steel). vanadis extra 4, ELMAX, S390, S290, K390, K490, etc. various materials, material origin, manufacturer, element Content testing, various performance testing, material and material report as the basis for selection, choose to use. Second, all processing and production processes are produced and processed in strict accordance with ISO9001, ISO14001, TS16949 and other quality management system certification standards. Third, check the manufacturing process: check the processing and manufacturing machines to ensure the normal operation of the machines and equipment. Fourth, the inspection of measuring instruments and tools, the staff measures the goods while they are doing the goods, and immediately terminates, corrects, and reworks if any problems are found. Five, the quality inspection department of the outsourced process inspects and measures to ensure compliance. Six, the quality inspection department of finished products, all inspections and inspections, to ensure that your product quality is 100% qualified. Seven, the packaging of the products of the packaging department is packed in strict accordance with the prescribed packaging standard process, foaming between the parts and products, safe and effective isolation and protection, and the appearance of the packaging box is stable for transportation inspection.