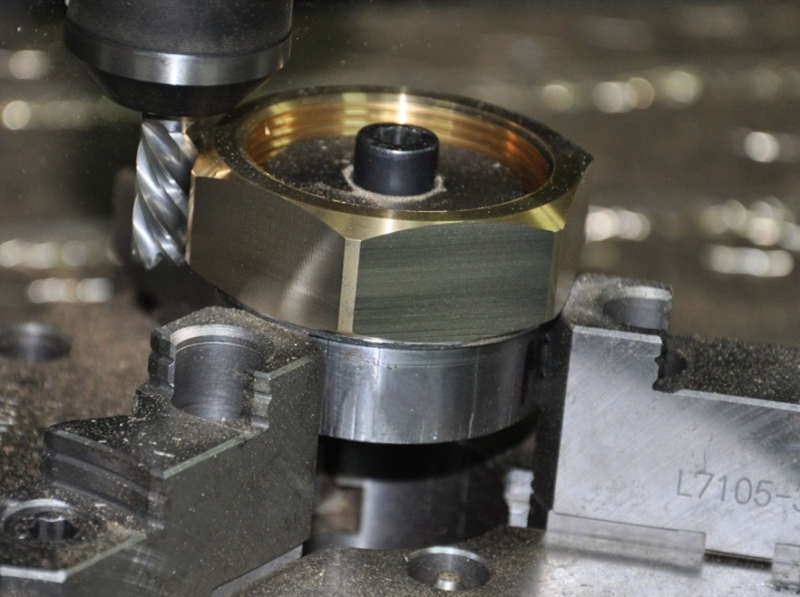

CNC precision machining In the production of rolling bearings, superfinishing is the last process after the workpiece is hardened. In addition to the requirement to improve the roughness, waviness and roughness of the workpiece, special requirements are also placed on the cross-sectional shape. This profile has a decisive effect on the optimal load distribution of the bearing. At present, too many calculation methods are available to calculate the corresponding geometric shape of each part of the bearing for each load design, such as logarithmic profile, which requires production technology. Optimization updates are carried out, while the cross-sectional shape can be calculated in batches using an advanced CNC grinding machine.

With the application of CNC technology to superfinishing machines, it is possible to purposefully influence the shape of the section after grinding.

So far, superfinishing cylindrical roller bearings and tapered roller bearings usually use shaped whetstone, because the small groove width of the raceway and rib cannot provide enough overrun for the whetstone. Therefore, the whetstone must have a wider contact surface between the two terminals in order to obtain a uniform material cutting amount. Modern superfinishing machines can superimpose a low-frequency large reciprocating motion on a high-frequency small oscillating motion. In this way, a much smaller (about 1/3) sodalite can be used than the width of the raceway. The whetstone moves along the workpiece generatrix so that the machined surface reaches the expected amount of material removal within the required machining time. The movement of the Whetstone also continued to the final position. This additional movement is usually hydraulically driven and the speed remains constant.